K9 Bros Treats are Backed by Food Science

Pet Age Staff //January 9, 2019//

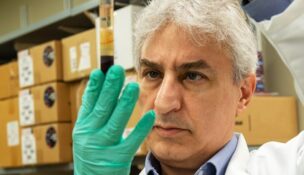

Pet Age recently spoke with David Feuerman, founder of K9 Bros, to learn the lengths he has gone to create a line of natural dog treats.

Q What inspired you, as a food scientist and graduate of Cornell University, to enter the dog treat market?

A I wanted to apply my knowledge to make better food for pets! Having worked for seven years in food manufacturing, first at Nature’s Bounty Vitamins, and then at a private label manufacturer of nutrition bars such as the Zone Bar and Pure Protein, I learned a lot about functional nutritional ingredients for people; ingredients of the highest quality and purity, in an amazing diversity, with constant ingredient innovation. It was in 2012 that my attention was drawn to dog treats after suspicious products, many from China, were causing terrible sicknesses in our canine companions. The more I researched about dog food, the more I uncovered the lower food quality standards for pets, and the more I wanted to do something about it. Treats made the most sense, since they can be nutritious snack, which was my expertise. That’s how K9 Bros was born.

Q What are the benefits of building your own factory to manufacture K9 Bros treats?

A Firstly, as a manufacturer of my own brand, I know the ingredients going in are real. I only source ingredients that are human grade, and the meat has been USDA approved for people.

I don’t need to list the occurrences in the pet food industry of intentional or unintentional ingredient substitutions with inedible by-product or inferior ingredients. I am always more suspicious of ingredients that are in powder or granule form, because it is obviously much harder to distinguish it. Larger manufacturers have quality control laboratories which should test to confirm the identity or potency of powdered ingredients, although many rely on ingredient suppliers for a certificate of analysis. To me the most suspicious ingredients are rendered proteins, which are labeled as “meals” such as “lamb meal.”

Many marketers of dog foods and treats use third party manufacturers—even some big pet food companies don’t do manufacturing. The cost to start up a manufacturing line is very high, requiring large volumes to justify the investment. Hence, many products are made by third party manufacturers on the same machines, and are the same as everyone else’s product except for some small changes and different colored packaging. The worst case in private label is when out-of-house products are not be made with the same level of care, and at best the manufacturer is just focused on running the production line smoothly at a sacrifice to innovation, since the more variables introduced, the lower the productivity for the manufacturer. It would be as if Ford, BMW, Toyota, and Tesla were all made in the same factory but with a different logo on the hood. .

Q How many different flavors comprise the K9 Bros lineup?

A K9 Bros now has four flavors, each in two sizes (except for Sweet Potato, which is just in the big bag. Three jerky flavors—Liver of Lamb, Heart of Lamb and Chicken Breast—and one veggie chew, Sweet Potato Medallions, which are seasoned with parsley to clean a dog’s teeth and freshen its breath.

All of my treats are seasoned with a vegetable, herb or seed to complement the nutrition of the main ingredient. For example, Liver of Lamb is very high in vitamin A and B, but not vitamin C, so I season the meat with broccoli florets, which are very rich in antioxidants. Then I add flaxseeds, which are a good source of Omega-3. All of my treats are formulated this way.

I recently added Heart of Lamb to my treats lineup, which took a lot of work enhancing my equipment. And now I’m looking forward to creating new flavors in 2019.

Q Where do you source the ingredients that are in your treats?

A I only source from human grade ingredient suppliers. I buy Lamb from the same supplier as Peter Luger and Whole Foods. Because my factory is located just outside New York City, I have access to food distributors that supply New York’s finest restaurants.

Since I buy only raw meats, I needed a large walk in freezer—which is extremely expensive to have installed—so I built one from scratch. It was a very difficult trade to learn, but I’m proud I did it all from start to I finish in two months. Having a knowledge of refrigeration comes in handy when you’re working with a lot of pure, raw meats.

Q How would you describe your manufacturing process?

A I keep it natural. My treats are preserved by dehydration, which is sometimes referred to as “air drying” or just “drying.” Warm, dry air between 110ºF and 170ºF is blown over the food and picks up moisture. Evaporation is very slow, so it takes a long time. To prepare the meat for the dehydrator, the meat going into K9 Bros treats have to be sliced into small uniform chunks. Then the chunks are pressed onto trays, maintaining a uniform thickness. Finally, the meat is dehydrated for several hours with warm dry air until enough moisture evaporates that the jerky becomes shelf stable. The main concern is mold growth, since spores are everywhere. The goal is no mold growth for a year or even longer. It’s hard to balance the texture with moisture. A soft chewy texture will sooner develop mold, but a dry product will be too brittle and dogs will really need water. Having water available for your dog, even for treats, is best to aid with swallowing and digestion.